Deep Processes

When do you need to standardize processes?

As your company scales, it is important to take the knowledge and best practices out of the existing team and turn it into an asset that new hires can use for training and improve their effectiveness.

Typically, when the tasks outgrow the time available to the entrepreneur and the initial “core” team, a company starts looking into standardizing and capturing their way of working.

Standardizing and optimizing routine processes is critical when it comes to taking off tasks of the founder’s shoulder. In which allows him/her to focus on more important activities like strategy, product decisions or founding rather than more mundane, but necessary, tasks like invoicing, customer service, etc.

This process also happens because of business scaling. Roles are getting more specialized and what was previously taken care by one person (e.g. accounting) is now taken care by two or more people (e.g. Active and Passive Invoices).

Therefore, the founder and the senior employees face the inevitable dilemma of not being able to carry out their usual tasks anymore but are afraid of delegating because their team would not do them “with the same quality or efficiency I would do”.

How can you document processes?

The typical and most sensible answer to relieve growth pains are documenting the company processes via Standard Operating Procedures (SOPs).

SOP captures the essence of how activities are currently carried out and spreads it to the rest of the team to ensure effectiveness and efficiency.

Alternatively, new hires could learn from senior employees for a while and receive mentoring, but this is quite time-consuming, and it is also unlikely that the new hire will have the chance to see all possible cases during its onboarding period.

Read our previous blog post “How to Write Great Standard Operating Procedures” for more details.

SOP Comes to Help

At a first glance writing an SOP may look trivial, after all, you just have to write what you do every day right? Wrong. What we do daily is filled with a countless number of assumptions that we almost never consider when we go about formalizing a process.

Say for example that you are writing the payment collection process. You specify a reminder one week before the deadline and another on the deadline date. In addition, a direct message one week after the deadline stating that the service will be interrupted if the clients cannot pay within days.

That seems to settle it, but what if the customer is the company’s biggest client and accounts for over 50% of company revenue? Would you have a different approach? Possibly.

Therefore, standard processes and procedures would need to incorporate not only the steps to be followed but also the general principles and objectives of the activity so that the employees have the right background and are in the conditions to work at their best.

Moreover, having the processes crystallized in a clear and open format has the added advantage of making the activity “auditable” and that is key for anybody to study, inspect, and improve the process.

Transparency is key for the continuous improvement of the organization. For more details regarding transparency, read our previous blog post “5 Ways To Increase Transparency Over Your Operations“.

People are ignoring my procedures

Processes are normally captured in long form text documents that are helpful for a company, but it also has several shortcomings.

Long form documents are good in the sense that they are comprehensive and are a great resource to refer to in case of need. They are like a dictionary or an encyclopedia, not your bedtime read but very important to be able to refer to them at times.

These Standard Operating Procedures can also be used as onboarding material to speed up and improve the training of new hires.

However, as humans, reading (and following) procedures is one of the least natural activities we can come up with. Think about it: when was the last time that you read the instruction manual of, say, your laptop, microwave or car?

Chances are that you jumped right to using your new purchase thinking “I’ll figure out as we go” right? This is absolutely normal and many times also it’s the best course of action.

People DO read the instruction manual in a specific instance: when things go wrong. Chances are that you opened the instruction manual of your laptop, microwave or car after it stopped working (potentially due to its misuse).

Also, even the most diligent people, those that read the instruction manual, sometimes forget about some relevant detail or step without realizing it.

So, how can we make sure customers and people in your company read the manuals when they are not natural-born manual readers?

How to ensure people read the SOPs

Defining processes and capturing them in Standard Operating Procedures is just half of the work: how to ensure people’s compliance? Processes should be automated or embedded in the company SYSTEMS.

Typically, process documents are completed when the people that are responsible for them think they are done. When they are asked with something, they can simply refer to the beautiful, written procedure sitting somewhere. If somebody does something wrong, they can blame him for not reading and following it.

In the best case, standard processes are actively promoted in the company and training sessions, to organize, update, and instruct everybody. However, these sessions should be done regularly as people need to refresh their knowledge and also for new hires.

While documented processes and procedures are good to clarify activities and a great starting point, the “right” way of doing things should be wired in the company system.

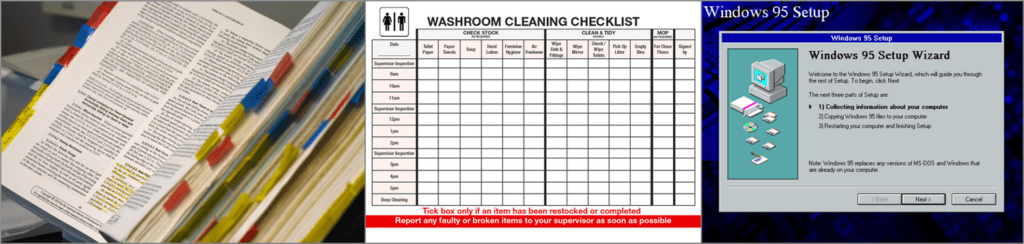

With the word “system” we don’t refer only to software but also to all tools and artifacts that are used daily by the company.

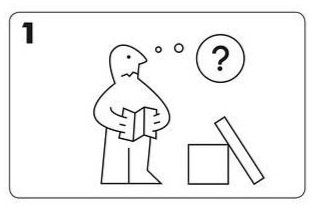

Consumer goods manufacturers do this all the time and try to wire the right behavior in the object itself. In fact, you can’t:

- Use the microwave with the door opened.

- Drive without a safety belt.

- Exit Microsoft Office without saving.

Think about the last time you entered a fancy office of a big corporation. Chances are you HAD to check in at the reception desk in order to get a badge that would get you through the turnstile.

Therefore, the best way to maintain and use SOPs is to actively think about how it can be embedded into your organization so that they become second nature.

Did you forget the procedure?

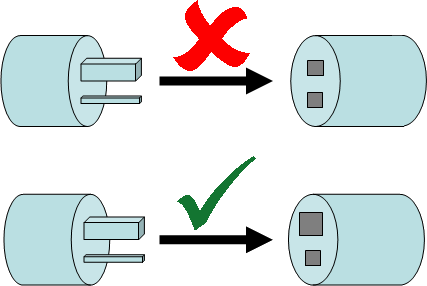

As mentioned above, your painfully compiled and beautifully written procedures can be embedded in your “rebel” company through several ways.

The most important being software systems. We can classify the process “enforcement” systems in 3 broad categories:

In companies software is the most natural way to ensure process compliance. Some examples include:

- Deals in the CRM are not closed if all information fields are properly filled (or maybe commissions are not paid until information is filled)

- In the ERP, an order cannot be sent to the warehouse for shipping if not paid

- …

Step-by-step guide for 100% process compliance

While it would be ideal to have all company processes locked and “fool-proof” that would not be efficient because compliance may be already high or the cost of non-compliance negligible.

The best way to make your processes “deep”, or embedded in your company DNA, is to approach your processes incrementally through these steps:

- List your processes and rank them by average compliance and criticality (i.e. cost of non-compliance)

- Select the one with the lowest compliance and highest cost of non-compliance

- Write a (simple) SOP and ideal workflow if not already present

- Identify the system / tools that are or can be used (in order of priority= a. Software b. Forms or Checklist c. (as a last resource) Process controllers / Incentives

- Repeat from 2